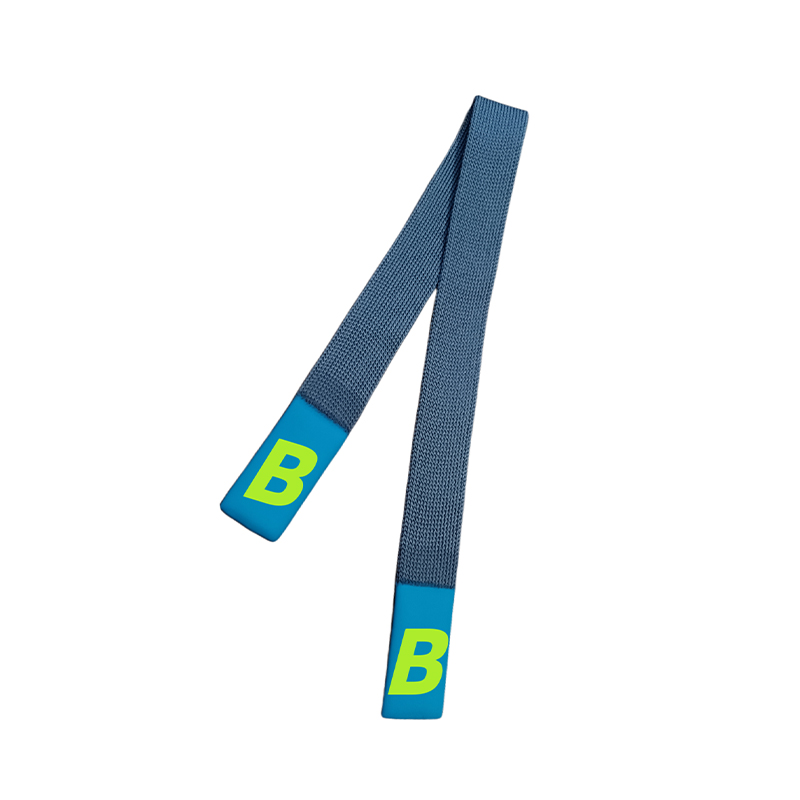

In the manufacturing of modern clothing, bags, and outdoor equipment, Liquid Silicone Rope End Caps are gradually replacing traditional plastic or metal accessories, becoming a key detail in enhancing product quality and durability.

- +86-13702392136

- wuqiang-072@163.com

- No. 282, Xitou Village, Hecheng Street, Gaoming District, Foshan City