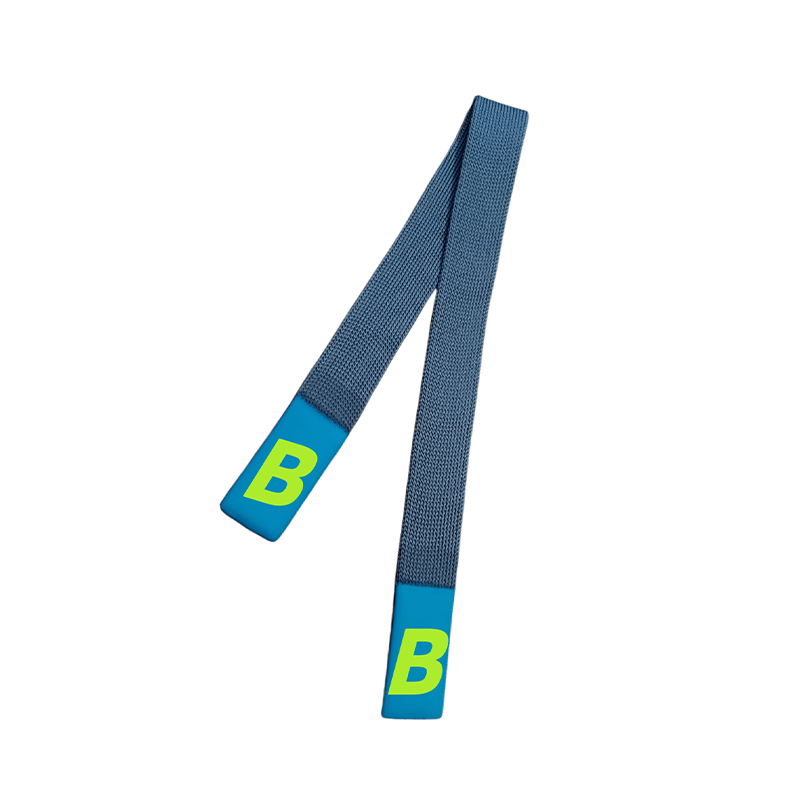

The seemingly small "sports equipment resin rope end cap"—a common accessory for the end of drawstrings—is shining brightly in various fields, including sports equipment, outdoor gear, high-end bags, and even trendy apparel, thanks to its unique material

- +86-13702392136

- wuqiang-072@163.com

- No. 282, Xitou Village, Hecheng Street, Gaoming District, Foshan City